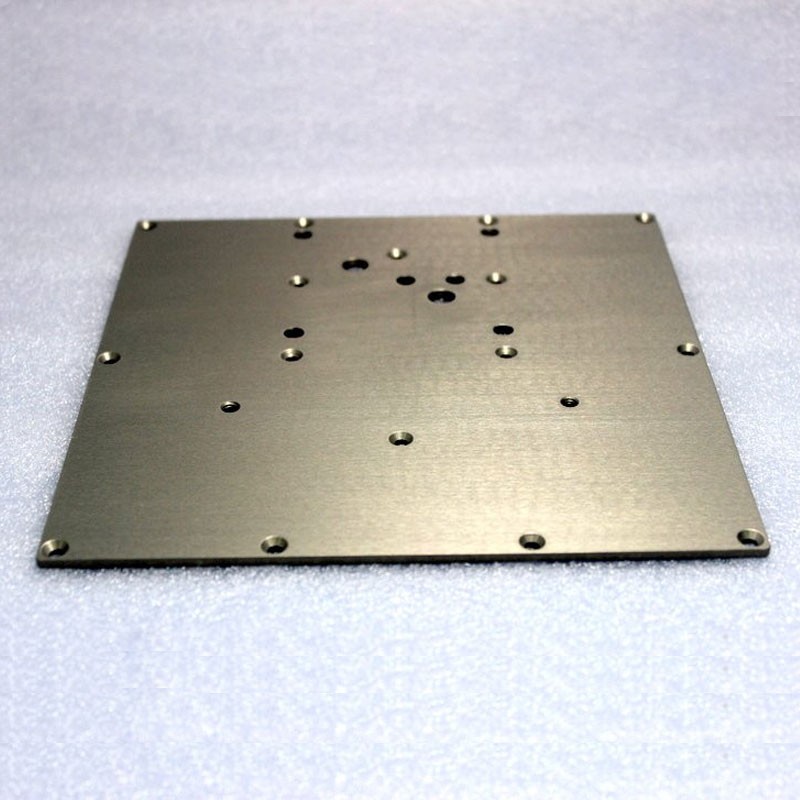

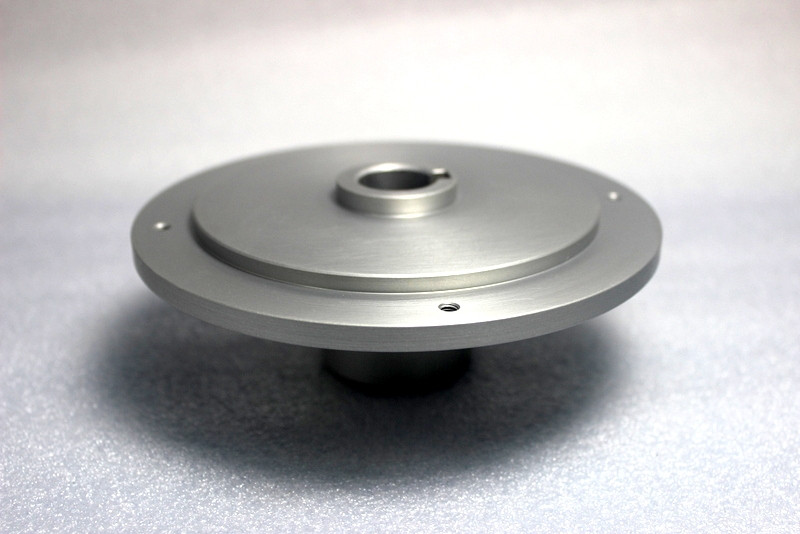

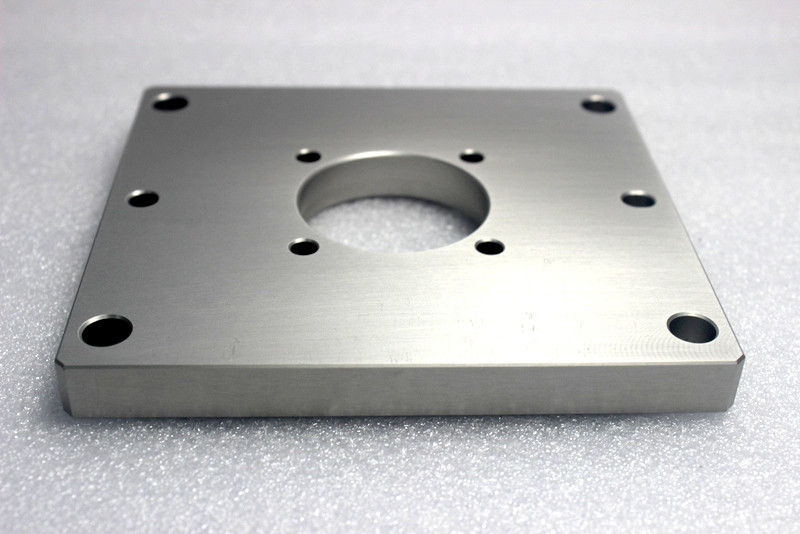

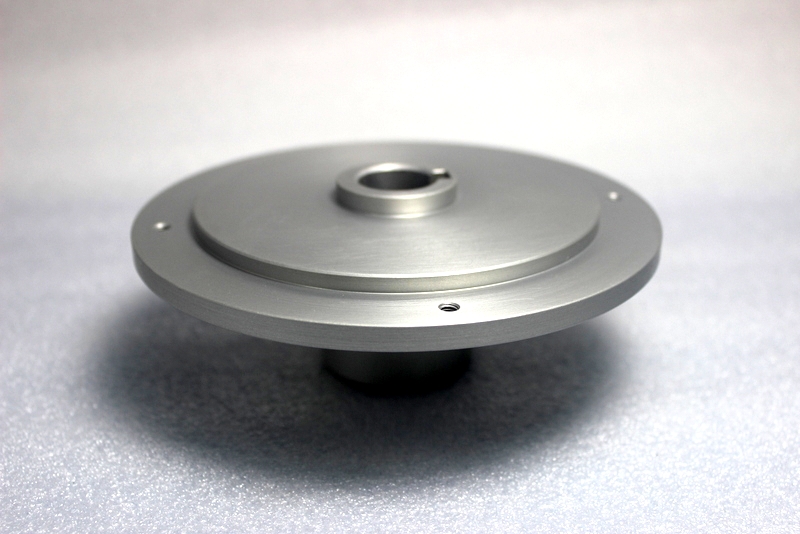

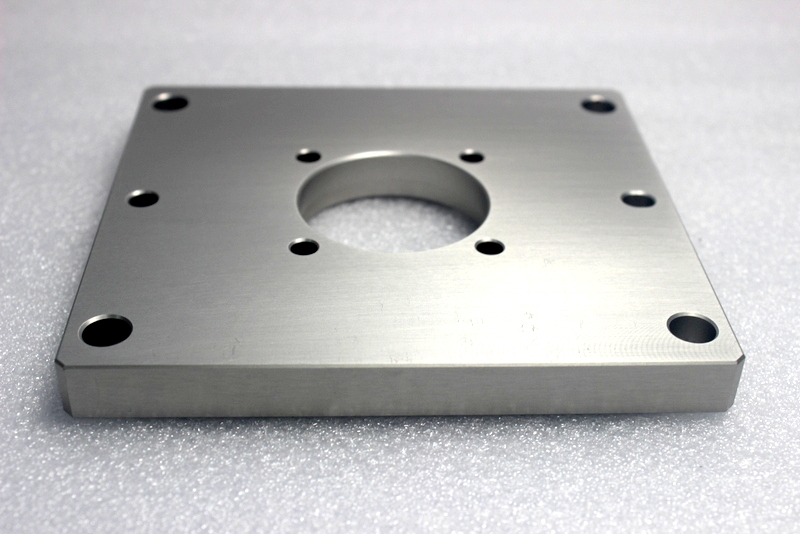

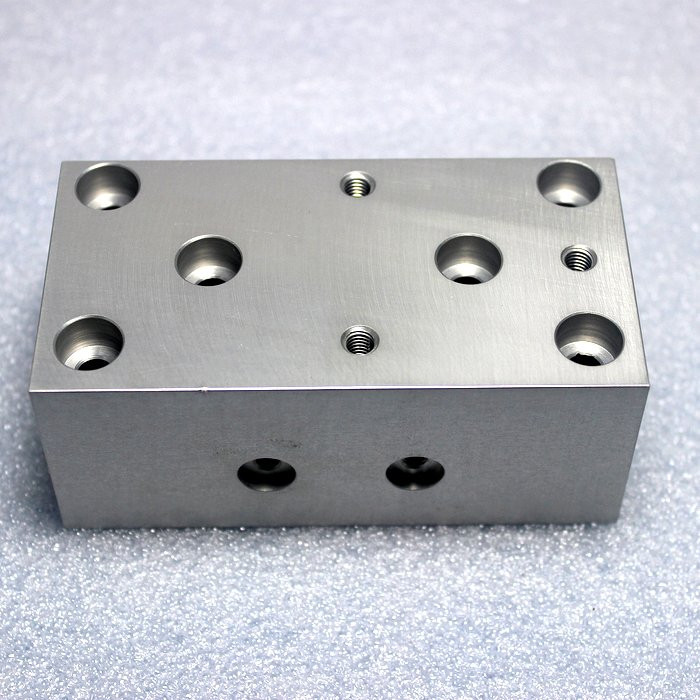

Custom, cost-effective machining solutions

• Precision CNC machining follow customer's requirements

• Complete CNC production, including precision CNC milling and turning

• Complex machining, assembly, weldments, and more

• Short run & Rapid lead times

• Contract manufacturing for prototypes & high volume order

Surface treatment is a process method to artificially form a surface layer on the surface of the substrate which has different mechanical, physical and chemical properties from the substrate. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For the metal castings, our common surface treatment methods are mechanical polishing, chemical treatment, surface heat treatment, spraying surface, surface treatment is to clean the surface of the workpiece, cleaning, deburring, deoiling, deoxidizing skin.

Product Description

Nickel plating, zinc plating, chrome plating role and difference:

1. Different colors

Galvanized appearance silver white.

The appearance of nickel plating is white and yellow.

Chrome plating consists of decorative chrome and hard chrome.

2. Different definitions

Galvanizing refers to the surface treatment technology of plating a layer of zinc on the surface of metal, alloy or other materials for the purpose of beauty and rust prevention.

Nickel plating is the process by which a layer of nickel is deposited on a metal or some nonmetal by electrolysis or chemical process.

Chromium is a kind of silver-white metal with a microstrip of blue. It is called chromium plating by means of electrolysis or chemical process to coat the metal or some non-metal with a layer of chromium.

3. Different features

Low cost of galvanizing, corrosion protection, the color is silver white.

Beautiful nickel plating, can be used as decoration, high price, slightly complex technology, color of silver white yellow.

There are two kinds of chromium plating, relying on the former kind is to play a decorative role, appearance bright, abrasion resistance better, rust resistance than galvanized, better than oxidation; The second is to increase the hardness of metal parts, wear resistance and so on, which is the functional part.

4. Different USES

Galvanized application in screws, circuit breakers, industrial supplies, etc.

Nickel plating is used in energy-saving lamp holders, COINS, etc.

Chrome plating is applied to the bright decoration of household appliances, electronic products, faucets, etc.

5. Different functions

The hardness of nickel coating is relatively high, which can improve the wear resistance of the product surface. Nickel plating is commonly used in the printing industry to improve the hardness of lead surfaces.

Because zinc is not easy to change in dry air, so in moist air, the surface can form a dense zinc carbonate film, can effectively protect the internal corrosion. This plating method is especially suitable for all kinds of strong acid and alkali fog corrosion environment.

Thin, bright and beautiful chrome coating. It is usually used as the outermost layer of multilayer plating. For protection purposes, zinc or steel substrates must be plated with a sufficiently thick interlayer and then coated with a bright interlayer of 0.25-0.5.

He Xiang provide metal precision machining services of non-standard to customers in a wide range of industries, from selection of raw materials and process methods, to surface treatment and safety shipping.

Welcome customers to consult.