Quality Control

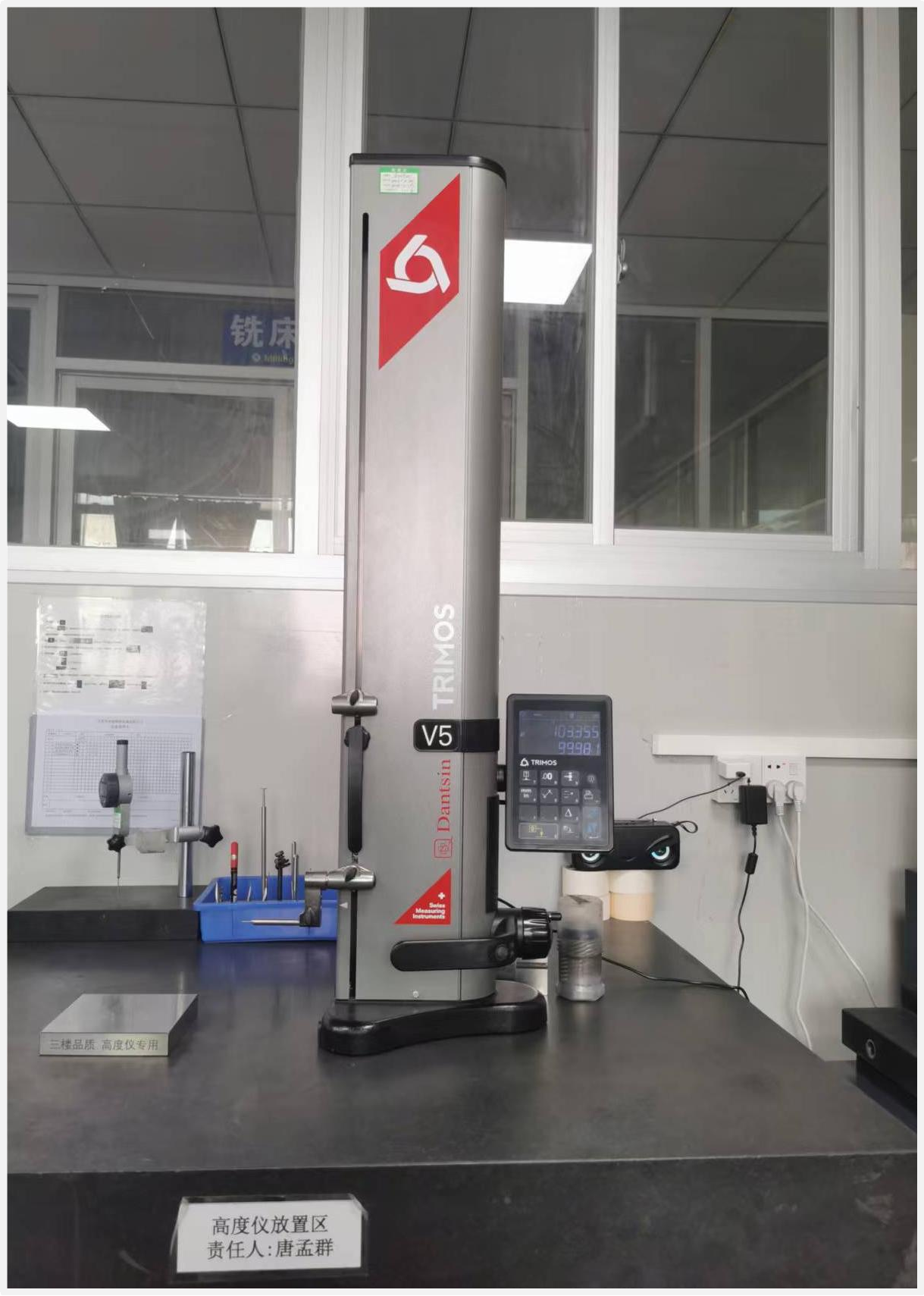

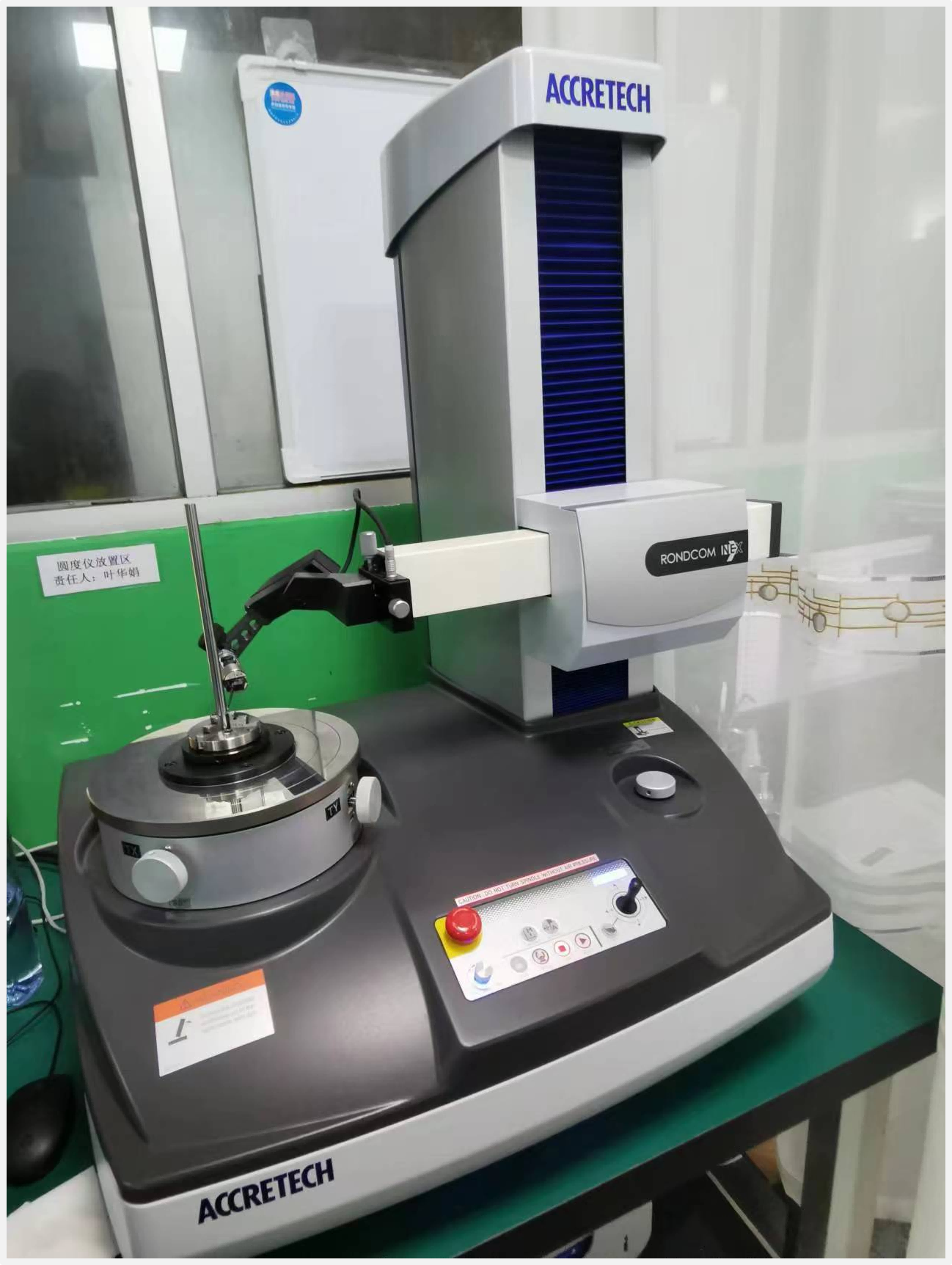

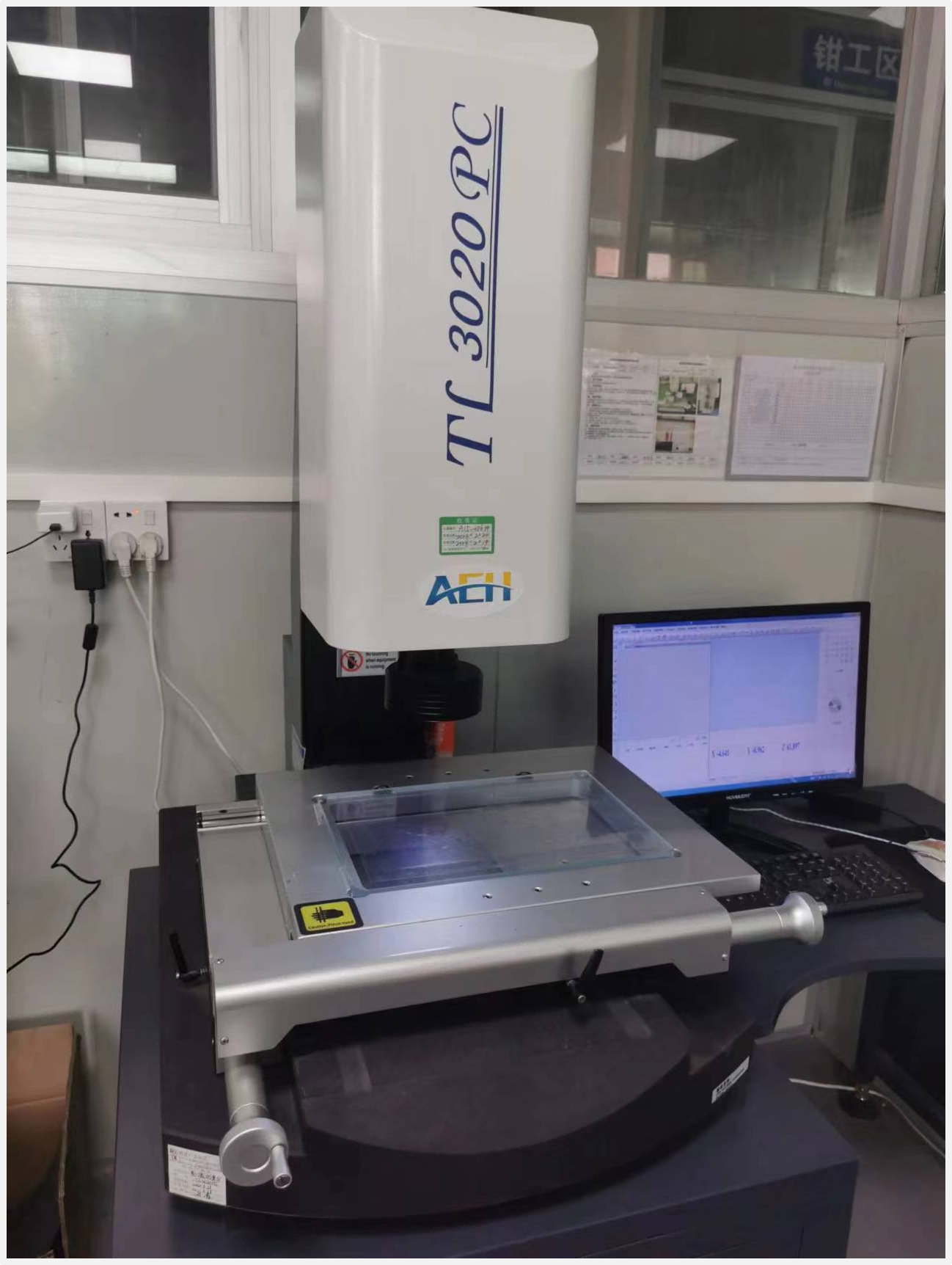

We use various types of inspection equipment including CMM, projector, digital height gauges and various other measuring equipment to continuously monitor and control our manufacturing accuracy. We perform incoming inspection, in-process inspection and final inspections to ensure that the parts meet your requirements.