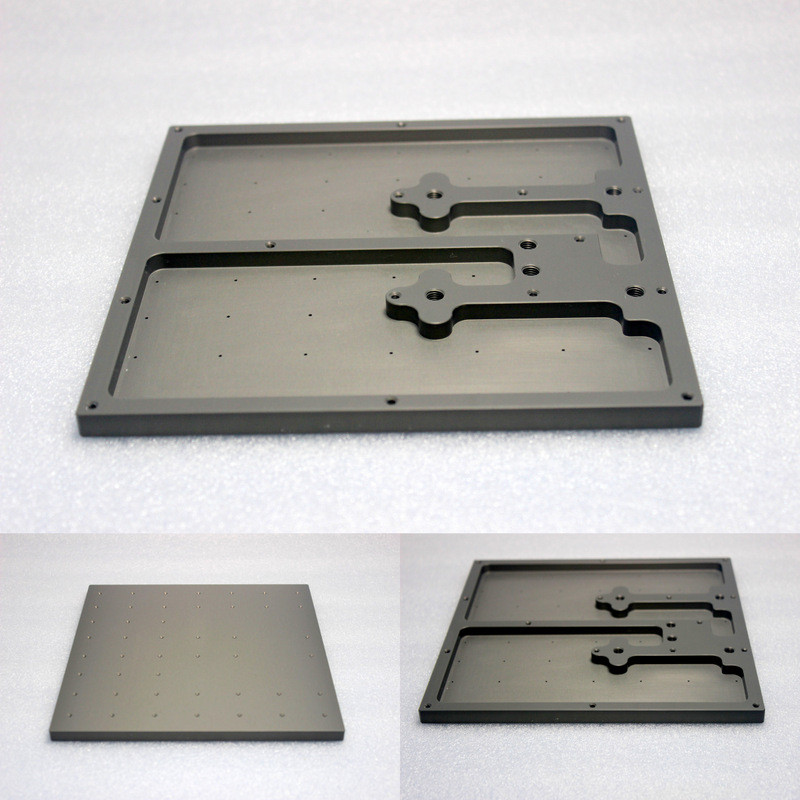

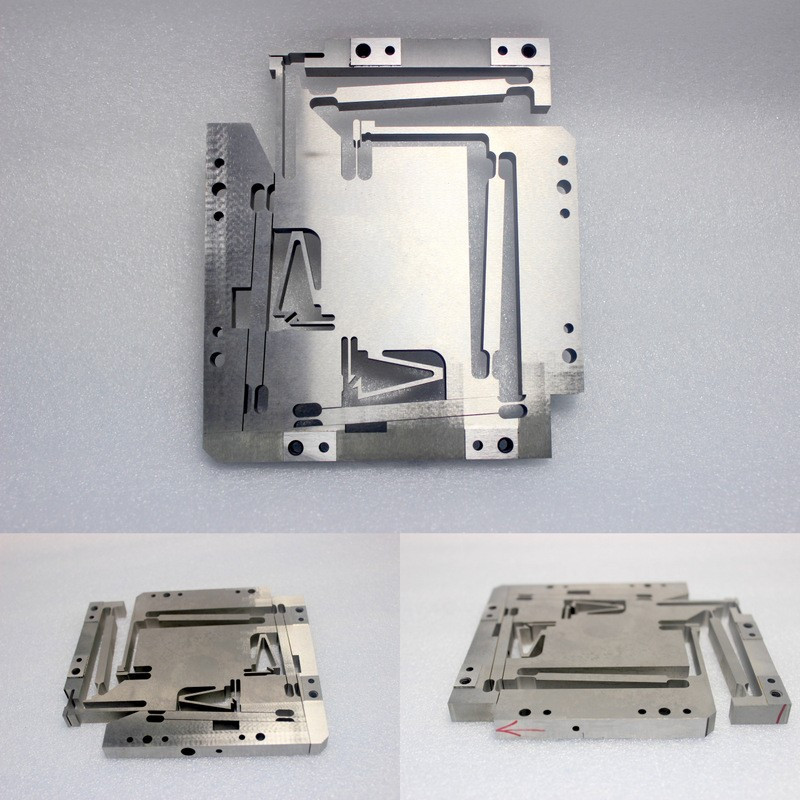

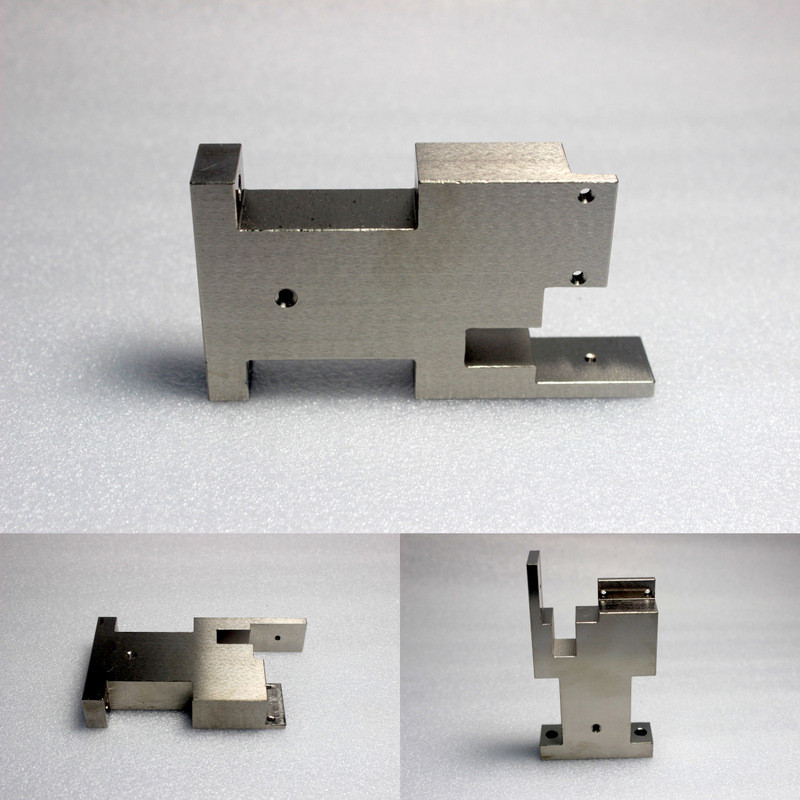

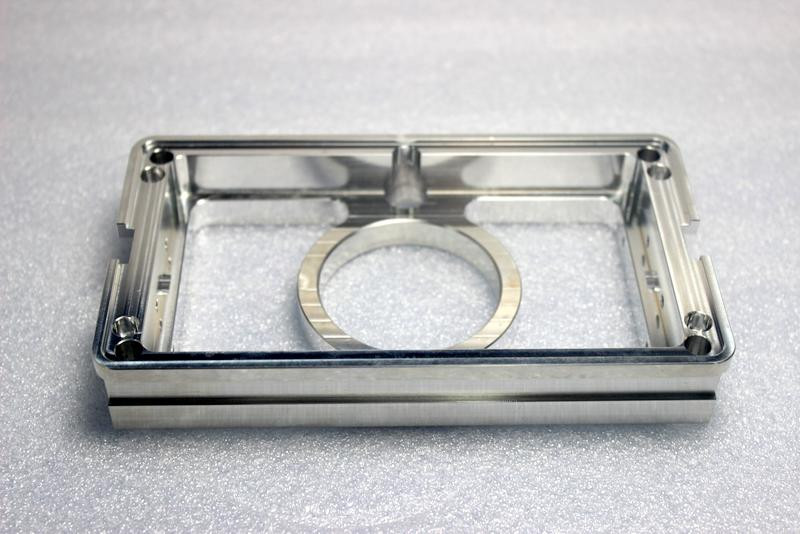

We can produce high precision products that meet the requirements according to all kinds of drawings provided by our customers.

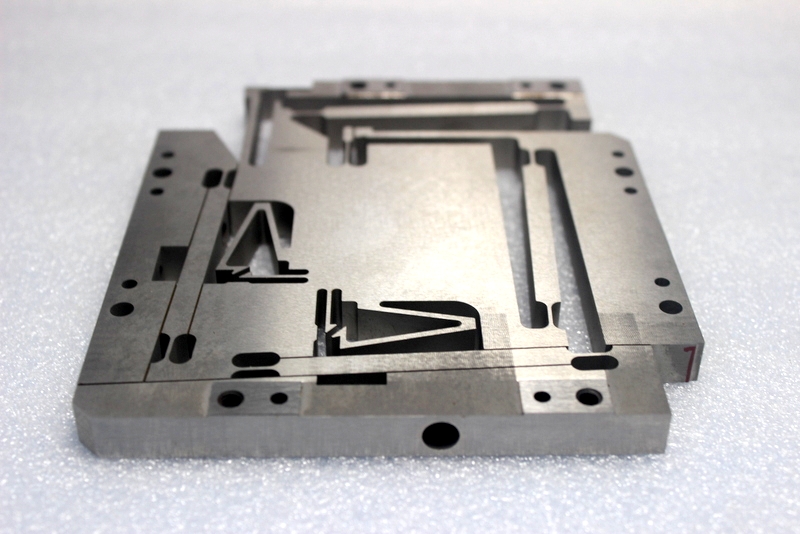

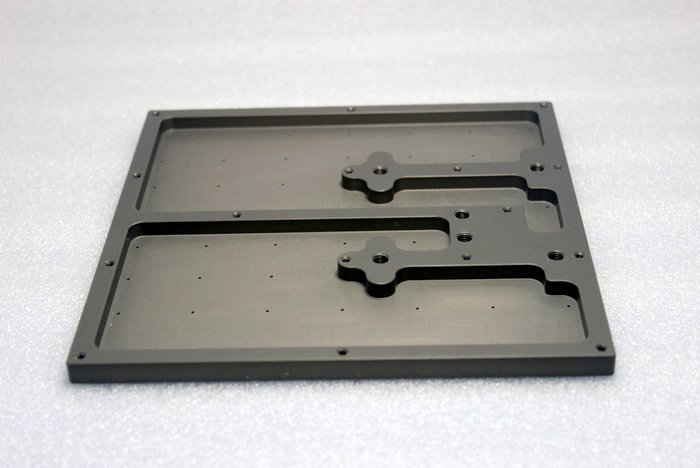

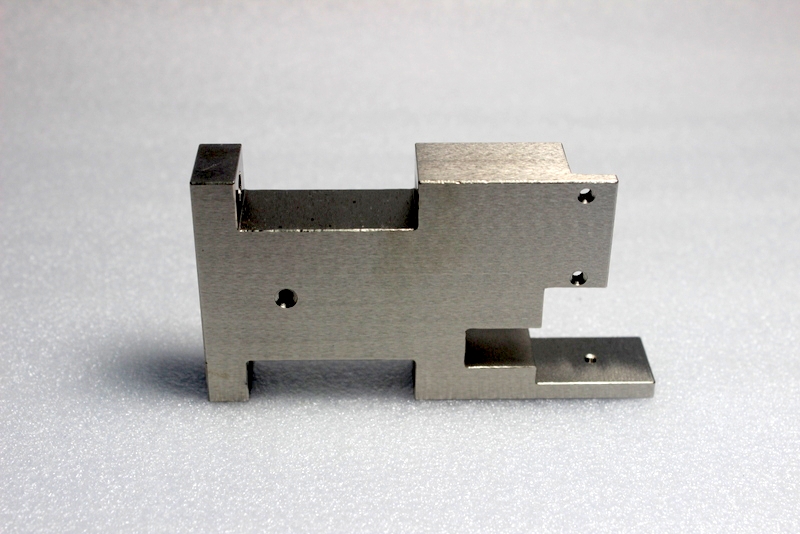

The machining accuracy of non-standard precision parts is extremely high. To achieve super-lubricated machining appearance and extremely high machining accuracy.

Our products are widely used in aerospace, communications, computer, electrical and electronic,automotive,machinery, instrumentation, valves, sheet metal, lighting, furniture, sanitary Ware and other industries, and are well received by customers. Production hardware stamping parts, drilling, teeth, polishing, whole set of products shipped.

Product Description

The machining accuracy of non-standard precision parts is extremely high. To achieve super-lubricated machining appearance and extremely high machining accuracy, it is natural that the cutter is required to be very high. If the tool is worn, The quality of the surface will be reduced. Moreover, when ultra-fine is cut closely, unlike the general cutting rules, its cutting speed is not limited by the standard life of the tool.

Processing of non-standard precision parts generally choose the smallest speed, which is based on the transmission characteristics and cutting characteristics of ultra-precision machine tools, because the minimum speed can minimize the appearance of roughness, thus ensuring the highest quality of processing. Of course, the premise is to ensure the quality of the machine tool to drive the high cutting speed and ensure the efficiency of the processing. Production and processing of aluminum parts of various sizes, processing precision up to 0.01 mm.

Advantage:

1. Hexiang is specialized in doing OEM/ODM precise products according to customers drawings or samples

2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

3. Certificates: ISO 9001:2008

4. Fast delivery

5. 10-year machining experience, using high quality raw materials, 100% quality inspection before delivery

6. Advanced equipment, excellent R&D teams and strict quality control system

So, we can achieve Competitive price with good qualit, low MOQ and short lead time.